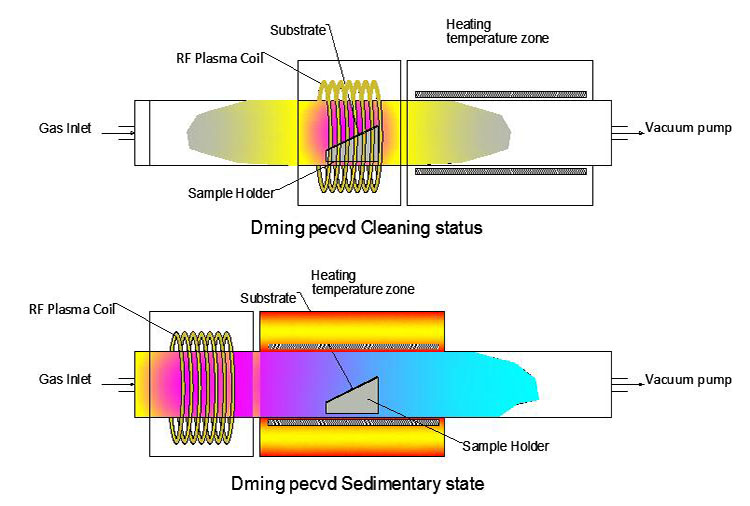

The PECVD system uses microwave or radio frequency to ionize the gas containing the film constituent atoms to form a plasma locally. The plasma has a strong chemical activity and is easy to react to deposit the desired film on the substrate. The system is widely used to deposit high-quality SiO2 film, Si3N4 film, diamond film, hard film, optical film, carbon nanotube (CNT), C/C composite material, SiC coating, graphite product coating, etc.

Features:

Features:

Standard Specification:

| Model | DM-12NT-PECVD | DM-14ST-PECVD | DM-17MT-PECVD |

| Max Temperature | 1200℃ | 1400℃ | 1700℃ |

| Working Temperature | 1100℃ | 1300℃ | 1600℃ |

| Heating Element | Resistance Wire | SiC | MoSi2 |

| Thermocouple | K Type | S Type | B Type |

| Temperature Zone | Number/Diameter/Length(Can Be Customized) | ||

| Temperature Accuracy | ±1℃ | ||

| Rated Voltage | AC220V50Hz/60Hz (can be customized) | ||

| Gas Control | Float Flow Meter/Mass Flow Meter | ||

| Vacuum System | Rotary Pump/Diffusion Pump/Turbo Molecular Pump(Optional) | ||

| RF Power | 100-1000W(Optional) | ||

| Optional Function | Touch Screen/Remote Control/Computer Monitoring | ||

| Can Be Customized | |||