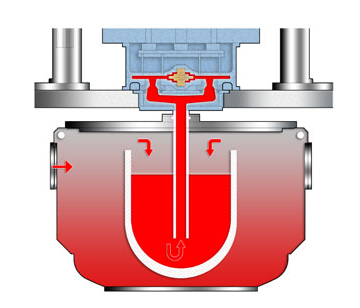

This equipment is mainly used for the heat preservation of molten aluminum in low-pressure casting of aluminum parts. The structure of the furnace body is crucible type (material is graphite silicon carbide).

The molten aluminum does not increase iron and does not affect the quality of castings; the whole furnace shell is welded by thick steel plates, sealed and pressure resistant, has a firm structure, and has a long service life; the heating method adopts natural gas, diesel or electric heating, which has a small footprint and high thermal efficiency; PID control temperature system, according to actual temperature control current transmission, to ensure safety and energy saving; furnace lining adopts high-quality ceramic fiber and nano thermal insulation board, heat loss is small, good insulation effect; equipped with aluminum liquid, furnace temperature, furnace pressure over-limit alarm devices; Rated capacity 150-1000KG, maximum withstand voltage 0.30Mpa

| Technical Parameter | |

| Holding Furnace Capacity | 200-3500 Kg (AL) |

| Maximum Pressure | 0.30MPa |

| Rated Temperature | 950℃ |

| The Temperature of Furnace Shell | ≤45℃+Room Temperature |